GE Oil & Gas uses the latest in metal laser sintering hybrid milling machines (metal 3D printers) at its Kariwa plant in Niigata Prefecture, Japan, to manufacture GE’s Masoneilan control valve parts with special configurations for use across various applications across the Energy industry.

GE Oil & Gas uses the latest in metal laser sintering hybrid milling machines (metal 3D printers) at its Kariwa plant in Niigata Prefecture, Japan, to manufacture GE’s Masoneilan control valve parts with special configurations for use across various applications across the Energy industry.

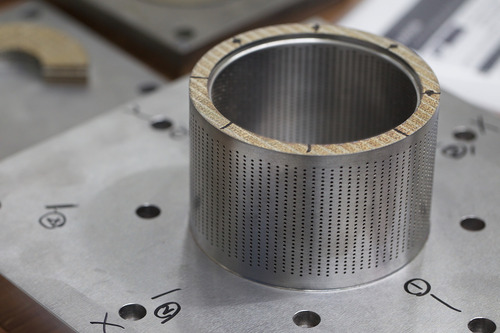

The use of metal 3D printing offers several benefits. One is that it is now possible to manufacture control valve parts with complex shapes, such as hollow structures, curved shapes, and meshes, which are difficult to make using conventional additive manufacturing methods, thereby allowing for a substantial improvement in design freedom. Another merit is that it makes integrated molding possible, which reduces the steps required for processing mould dies, realizing faster manufacturing times and lower cost when compared with conventional methods. An example of the substantial contribution that the metal 3D printer can make to reducing delivery times is that it allowed for a specially shaped component, which would have taken an estimated three months to produce using conventional manufacturing methods, to be manufactured in about two weeks.

Alvin Jeffers, Senior Executive for GE Oil & Gas’ Global Supply Chain said, “A completely new form of product manufacturing has been realized through the advanced technology of the metal 3D printer and the full utilization of that technology through the outstanding creativity of Japanese designers. Advanced manufacturing has changed the conventional definitions and mechanisms of manufacturing, namely design and production, while offering an abundance of merits to customers, such as faster manufacturing times and greatly reduced costs. I am confident that it will become a new standard in the manufacturing industry in the near future.”

Mitsuaki Sakonju, the Kariwa plant Director, said, “We consider this metal 3D printer to be the best means for delivering high-grade products that meet the customer’s individual needs in the shortest amount of time and with increased cost competitiveness. GE’s Kariwa plant will continue to work to provide its customers in Japan with the most suitable control valve products and solutions in the shortest amount of time possible by making full use of its accumulated knowledge and the latest technology.”

No comments:

Post a Comment